In a two-pipe steam heating system, problems will happen if the boiler and the parts that make it work are neglected and not maintained properly. What I mean about problems are simple things that make the situation look huge when they aren’t. If your steam system is not heating correctly, and you feel like tearing the boiler out and pipes stop! Take a look at this steam boiler correction.

The boiler feed tank

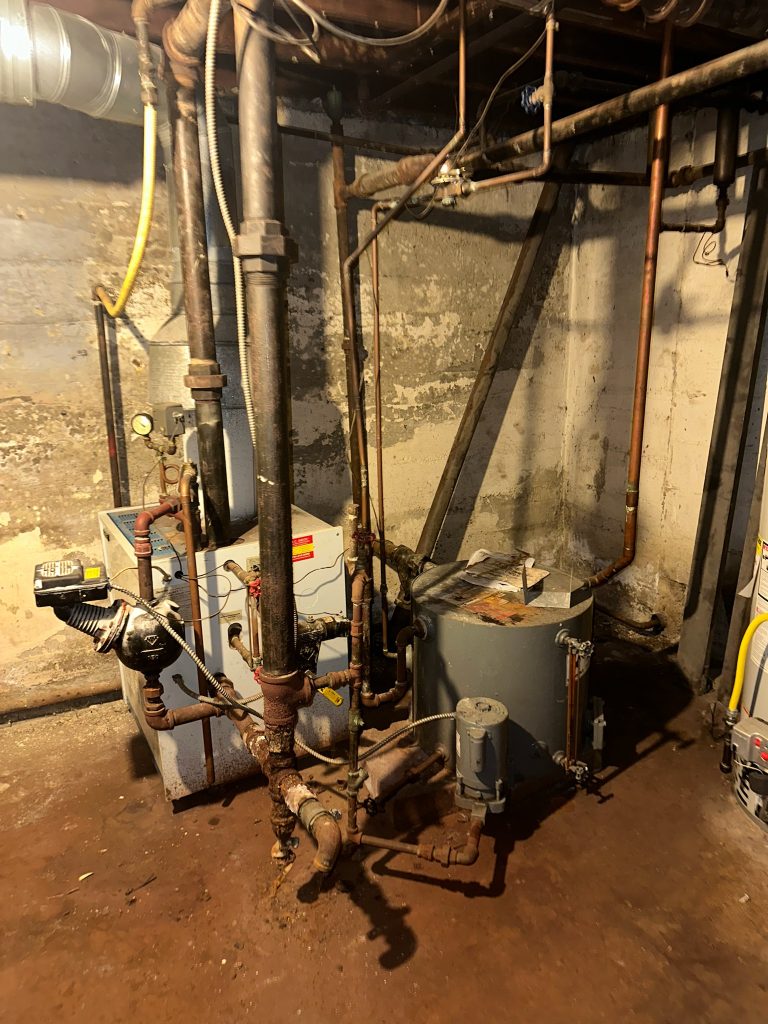

When I got to this house to look at this customer’s steam boiler problem, I couldn’t believe what I saw. They had an older Slant/Fin Galaxy 300,000 BTU GXH 300 HEPZ, which was still in good shape, but the installer installed the near boiler piping incorrectly. The main supply pipe had a big hole from water and steam colliding cycle after cycle. Right next to the boiler was this huge boiler feed tank piped right into the boiler at the relief valve tap.

Here’s a video from this job:

Is the boiler feed tank necessary?

If you’re unfamiliar with a boiler feed tank, it collects condensate water and feeds make-up water. The tank then adds the water into the boiler when it goes into a low water situation, resulting from a low water cut-off. This way of adding water to the boiler can lead to flooding if the feed tank is installed wrong. If your told a feed tank is needed to correct a problem for your steam boiler for low water don’t believe it until the following problems are checked:

- The near-boiler piping for the boiler being installed wrong and against the manufacturer’s recommendations or the usual standard piping method.

- Second, the wet return pipes that bring the condensate water back to the boiler would be clogged.

A sign of clogged return pipes would be banging and clanking in the radiators and supply pipes because the condensate can’t drain back to the boiler. These are simple little problems that can cause bigger problems if the wrong company looks at your steam boiler. Does this make sense? It should. Take a look at the pictures of the clogged return pipes I took out on this job.

As you can witness above in the two pictures, the problem was not the water coming back to the boiler fast enough. But rather it was the clogged wet return pipes stopping the water from coming back.

The old boilers did not have feed tanks despite the fact they ran wild on coal. So why would you need a feed tank on a newer boiler? I’ve been told that the newer cast iron steam boilers don’t hold as much water as the old boilers. That is somewhat true, but it’s not entirely correct.

When a feed tank is the solution

A boiler feed tank would be necessary only if there isn’t enough height difference between the (A) dimension, the height from the boiler’s water line, and the lowest horizontal steam supply piping. The static weight of the water at the end of the steam main will circulate the condensate from the steam pressure through the wet return into the boiler at the Hartford Loop. The boiler’s steam pressure should never exceed one and a half pounds. The A dimension height makes the static head pressure to push the condensate back to the boiler. An adequately installed steam boiler with correct near-boiler piping will never need a boiler feed tank. For everything to work by gravity, the A dimension must be at least 28 inches or higher.

Do you have a boiler feed tank?

If you have a feed tank and are having similar problems, schedule service with Vince and get your heating system fixed right.